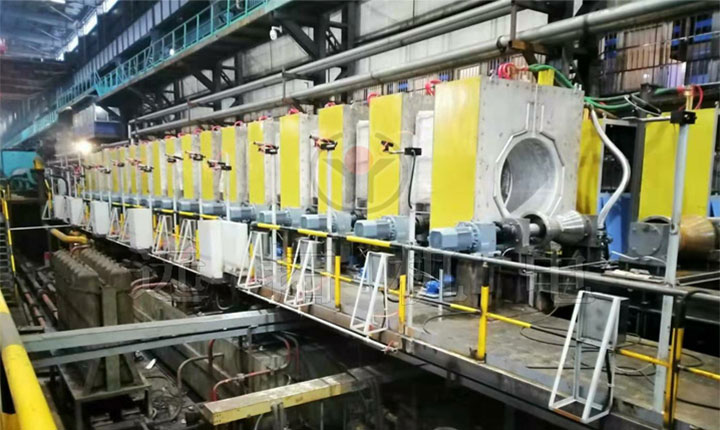

Steel pipe spraying equipment

Features:

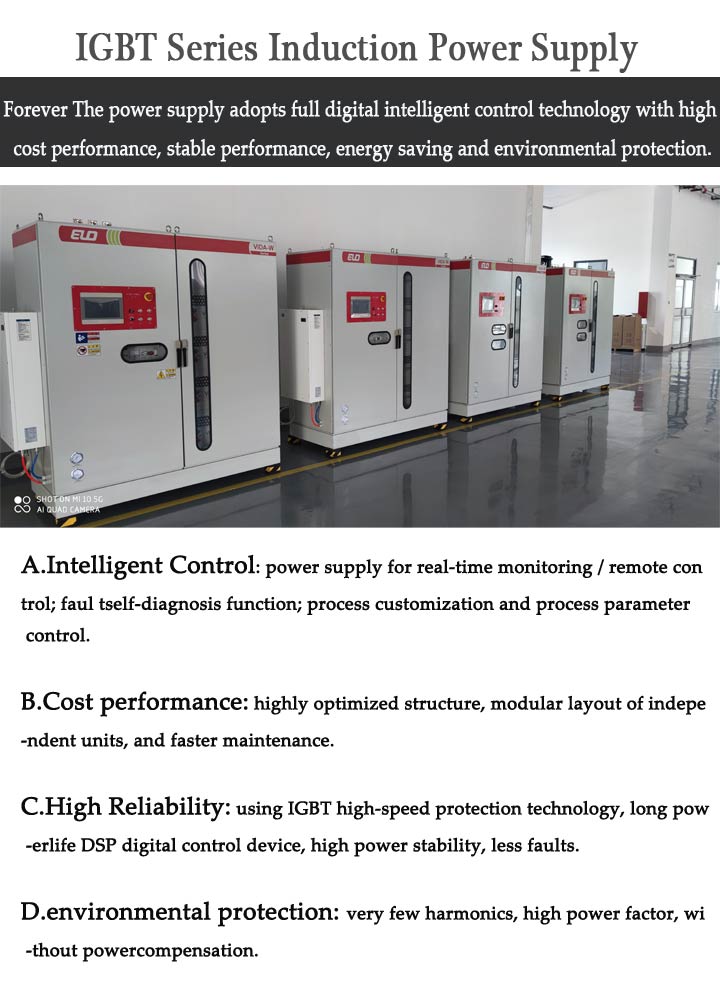

Hebei Forever Electromechanical is the preferred fully automatic intelligent steel pipe spraying equipment, with an energy-saving effect of over 45%. Hebei Forever Electromechanical customizes suitable steel pipe spraying equipment, steel pipe external anti-corrosion equipment, and Forever is a professional manufacturer of steel pipe external anti-corrosion equipment.

Product Detail

Application Video

Product Tags

Equipment name: steel pipe spraying heating equipment

Equipment brand:Forever Electromechanical

Non standard customization: Yes

Size range: above 20mm in size

Payment method: 30% down payment, successful acceptance, and full payment of the remaining balance.

Delivery deadline: within 30 days

Special advantages of steel pipe spraying equipment:

1. The steel pipe spraying heating equipment is controlled by a PLC fully automatic control system, combined with a human-machine interface and a touch screen to display data, saving labor.

2. The conveyor roller is made of 304 non-magnetic stainless steel, and the roller axis forms an angle with the workpiece. The workpiece rotates at a constant speed while moving forward to maintain stability.

3. The feeding system adopts a well-known brand reducer , which is controlled by an independent frequency converter.

4. The steel pipe spraying equipment is dust-free, pollution-free, and free of toxic gases during the production process.

5. The steel pipe heating equipment is controlled stably by the American Raytheon thermometer, with uniform heating and uniform spraying after heating.

6. The heated steel pipe does not exhibit decarburization, cracks, or deformation.

After sales service for steel pipe spraying equipment:

Before delivering the steel pipe spraying equipment, the supplier shall provide technical training to the user, including both theoretical and practical aspects. The intermediate frequency induction heating equipment is installed, debugged, and trained before leaving the factory or after arriving at the user, until the user’s operator can independently produce qualified products. The warranty period is 12 months. During the warranty period, if the medium frequency induction heating equipment is damaged due to non-human factors, the supplier is responsible for maintenance or replacement. During the quality assurance period (from the date of shipment), if there is any non-human damage to the parts, the company will provide them to the purchasing manufacturer free of charge

Outside the quality assurance period, the company will provide the purchasing manufacturer with a discounted price for a fee

The supplier shall provide free instructions and maintenance manuals for the main electrical appliances and components, as well as instructions for the use of steel pipe spraying equipment and maintenance materials for the entire machine. The supplier shall also provide installation drawings for water, electricity, gas, and equipment of steel pipe spraying equipment.

The supplier is responsible for assisting with installation, debugging, and training services. After the steel pipe spraying equipment leaves the factory, the three guarantees are 12 months. After the three guarantees are 12 months, the accessories of the steel pipe spraying equipment are supplied at a discounted price.