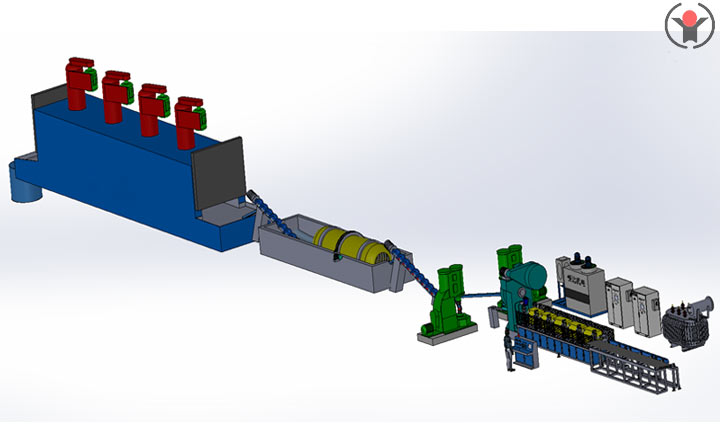

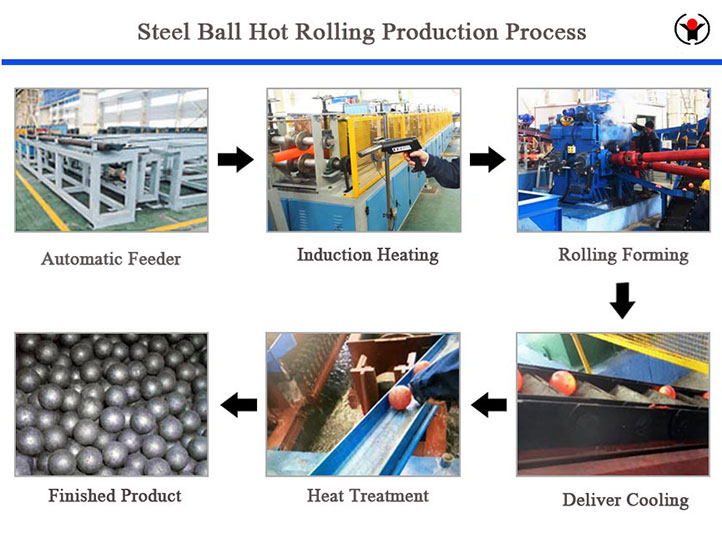

To ensure the long-term stable operation of the steel ball hot rolling production line , improve equipment life, and reduce failure rates, a scientific maintenance plan needs to be developed, covering mechanical, electrical, hydraulic, and process systems.

1. Mechanical system inspection for steel ball production line

Rolling mill roller and bearings: Check the lubrication condition to ensure no abnormal noise or overheating (temperature ≤ 70 ℃).

Transmission chain/gear: Check for wear and tightness, and add lubricating grease (such as molybdenum disulfide).

Mold (rolling mill, guide): Observe surface wear and cracks, and promptly repair or replace them.

2. Electrical system inspection

Induction heating power supply: Check the cooling water flow rate and temperature (inlet water ≤ 35 ℃), clean the filter screen.

Motor and frequency converter: Monitor current fluctuations and ensure the normal operation of the cooling fan.

Sensors (infrared temperature measurement, encoder): Clean the probe and calibrate data accuracy.

3. Hydraulic and Pneumatic Systems

Hydraulic station: Check the oil level and temperature (40~60 ℃), and replace the filter element in a timely manner if there is a blockage alarm.

Cylinder/oil cylinder: Check for seal leakage and whether the action is stuck.

4. Process parameter monitoring

Rolling temperature: Ensure uniform heating of the steel billet (such as 1050-1150 ℃) to avoid cracking caused by low-temperature rolling.

Rolling force and speed: Record data and troubleshoot mold or transmission failures in case of abnormal fluctuations.

By strictly implementing the maintenance plan, the failure rate of the Forever steel ball hot rolling equipment can be reduced by more than 30%, significantly improving the overall equipment efficiency (OEE).

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-25-2025