Hot Rolled Steel Ball Production Line

Features:

1.Available Power:100KW-8000KW

2Available Frequency:500Hz-8000Hz

3.Heating Diameter:Ø16-150MM

4.Steel bar length is unlimited.PLC Closed-Loop Control;Unmanned Control Process of Automatic Feeding and Heating.

Product Detail

Application Video

Product Tags

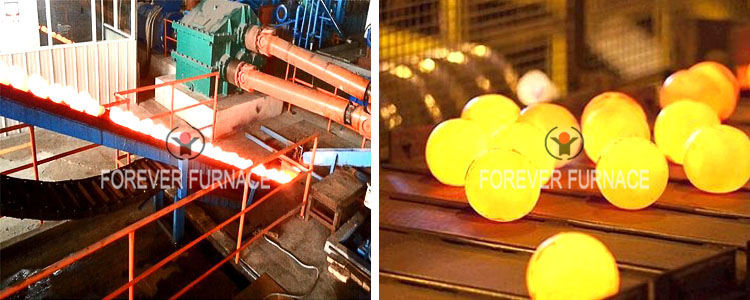

Forever Furnace is dedicated to research the reliability and energy-saving of hot rolled steel ball production line and we take more time to develop the higher power induction heating equipment.

In 2009,we designed and manufacture the first 2500KW skew rolling line used for continuous steel bar heating in China.The skew rolling production line can heat the steel bar of Ø19- Ø150 with power from 160KW to 2500KW and frequency from 500Hz to 8000Hz.But the length of steel bar can be according to the customers’ specific requirement.

In 2012,we designed and manufactured 4000KW steel bar induction heating line.It save our customer great electricity.

Recently,our higher power equipment reduce the labor cost and increase the working efficiency with PLC whole process control.We supply thousands of sets of heating equipment and heat treatment equipment for hundreds of forging plants.

Hot Rolled Steel Ball Production Line Application

The Advantages for Forever Furnace Hot Rolled Steel Ball Production Line:

(1)Automatic control for quenching temperature to ensure the quenching quality.

(2)The red steel billet will be sent to skew rolling mill for rolling steel balls continuously.The output of the skew ball rolling mill is 40-120 balls per minute each rolling mill.

(3)Quenching and tempering for the rolled red steel balls to make them get high and uniform hardness.

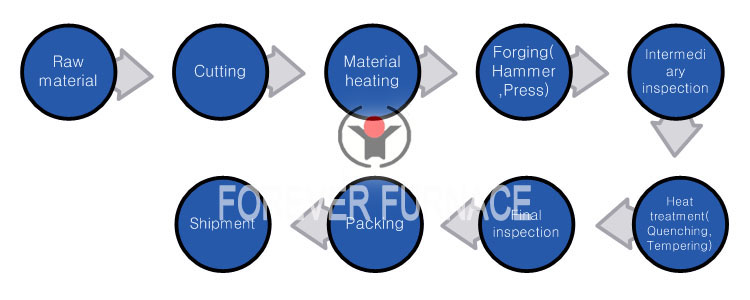

The Process for Hot Rolled Steel Ball Production Line:

The Common Current Frequency for Hot Rolled Steel Ball Production Line:

1.High frequency heating:100~500KHZ,usually use 200~300KHZ,mainly used for medium and small work piece.

2.Medium frequency heating:500~10000HZ,usually use 2500~8000HZ,mainly used for shaft with bigger diameter and large gear.

3.Line frequency:50HZ,mainly used for surface quenching with bigger part diameter.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.