Steel pipe welding joint annealing equipment

Features:

Equipment name: steel pipe wire weld annealing equipment

Equipment brand: FOREVER Electromechanical

Non-standard customization: Yes

Workpiece material: carbon steel, alloy steel, etc

Delivery time period: within 20 days

Product Detail

Application Video

Product Tags

Suitable for steel pipe, high-frequency welded steel pipe, stainless steel pipe and other metal workpiece annealing treatment.

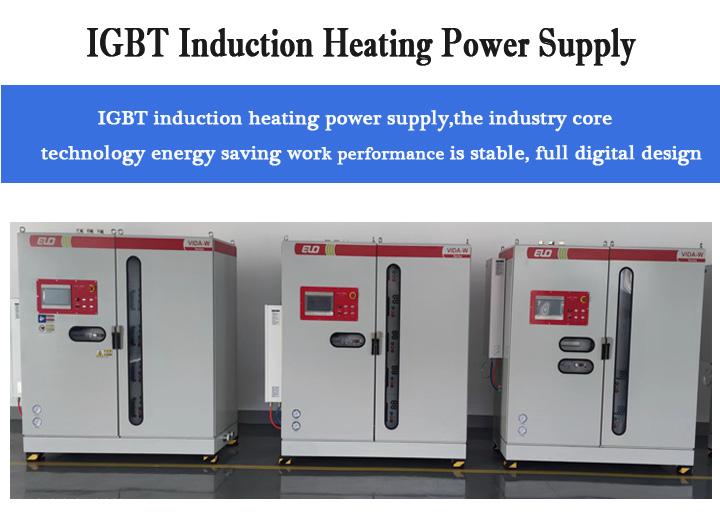

Steel pipe welding induction annealing furnace adopts SCR intelligent series resonant intermediate frequency power control characteristics:

[1] Parallel resonance design, phase shift, mature stability; more advantages in high power range above 3000KW;

[2] DSP control, fast capture phase-locked start, meet the frequent start and stop, high success rate;

[3] Frequency conversion and variable load adaptation, frequency adaptation range of 200-10000Hz, induction furnace replacement and automatic matching, without any manual adjustment;

[4] T2 copper exhaust is used in the cabinet, treated by sandblasting and passivation; low leakage feeling and oxidation resistance, effectively reduce the line loss;

[5] Full touch screen control, pure digital setting, with complete process records and strict level authority. Main parameters can be one key restore factory settings;

[6] The single power supply is 50-6000KW, and the frequency is 200-10000Hz.

Characteristics of Induction annealing steel pipe process machine:

▲ Temperature closed-loop control, using two-color American Leitai infrared thermometer to control the temperature, with the function of real-time display of the current temperature, so that the temperature difference of steel pipe annealing is controlled within 10℃.

▲ Carefully designed sensor with high heating efficiency, fast heating speed; the sensor copper tube turns is uniform, the temperature is easy to control, the sensor insulation performance is good, around 10 thick yellow insulation plate for protection, long service life.

▲ PLC man-machine interface, highly humanized operation instructions, full digital, high depth adjustable parameters, according to different countries and regions can provide the corresponding language switching

▲ Steel pipe wire weld annealing equipment components are using domestic and foreign famous brands, quality is guaranteed.

▲ Professional formula management system, after selecting the steel type and version parameters to be produced, automatically call the relevant parameters, no longer manually record, consult, input the value of various workpiece parameters.