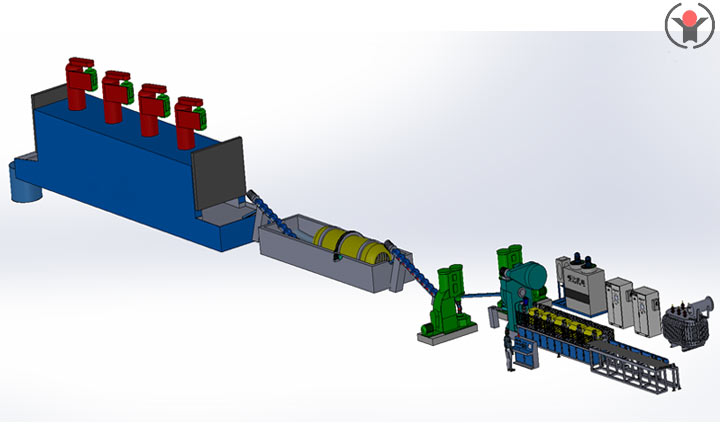

Steel ball rolling production line

Features:

Main technical parameters of the equipment: ● Workpiece material: B2 B3、B6、70Cr2、75Mncr、65Mn、60Mn、GCr15、40Cr、45#。 Power supply system: KGPS200-6000KW or IGBT200-2000KW, with an hourly output of 0.2-16 tons. Infrared temperature measurement: An infrared temperature measurement device is installed at the discharge end to ensure that the temperature of the bar before entering the rolling mill is consistent. ▲ Energy conversion: Heating to 930 ℃~1050 ℃ consumes 260-280 degrees of electricity

Product Detail

Application Video

Product Tags

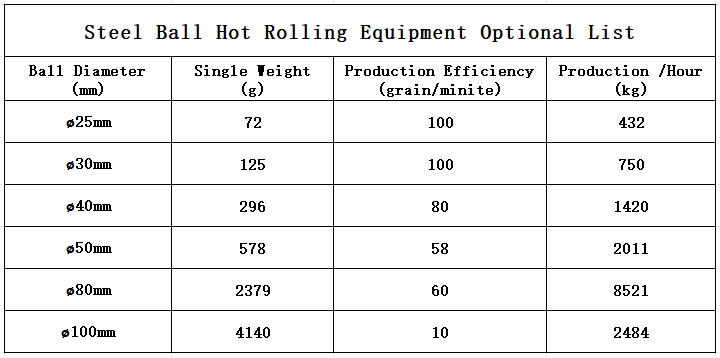

Main technical parameters of hot rolled steel ball heating line :

Workpiece material: B2 B3、B6、70Cr2、75Mncr、65Mn、60Mn、GCr15、40Cr、45#。

Power supply system: KGPS200-6000KW or IGBT200-2000KW, with an hourly output of 0.2-16 tons.

Sensor design: variable pitch, temperature gradient design, for higher efficiency.

Elastic adjustable pressure roller: enables workpieces of different diameters to feed at a uniform speed, and the roller tracks and pressure rollers between the furnace bodies are made of 304 non-magnetic stainless steel and water-cooled.

Infrared temperature measurement: An infrared temperature measurement device is installed at the discharge end to ensure that the temperature of the bar before entering the rolling mill is consistent.

▲ Energy conversion: Heating to 930 ℃~1050 ℃ consumes 260-280 degrees of electricity.

Working principle of steel ball forging production line :

The working principle of spiral pass oblique rolling is shown in the figure. Two rolling rolls with spiral passes cross each other’s axes, and the rolling rolls rotate in the same direction to drive the circular rolling piece to rotate and move forward. Under the action of the spiral pass, the rolling piece forms a blank of the rotating body part. The deformation of oblique rolling is mainly due to axial extension of diameter compression.

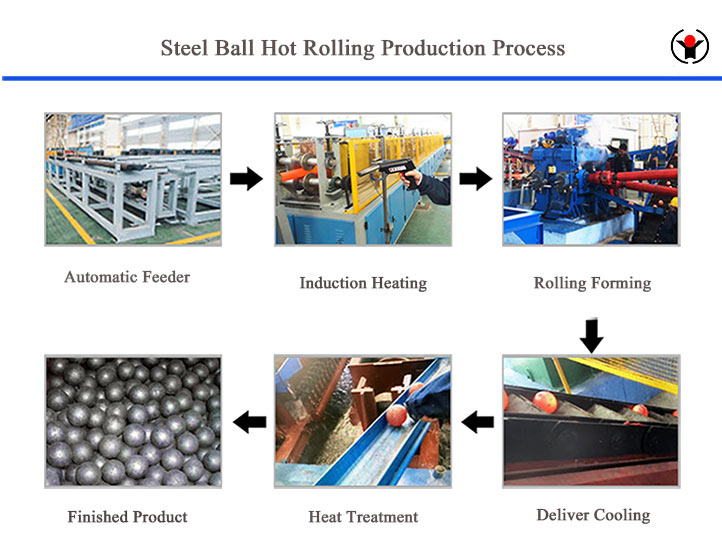

Advantages and characteristics of steel ball hot rolling production line :

1. The production efficiency of steel balls is high. Due to the fast speed of the intermediate frequency heating furnace, it meets the rolling requirements of the rolling mill, greatly improving the production efficiency of steel balls.

2. The degree of automation is high, and the entire set of steel ball hot rolling equipment is fully automated from feeding to rolling and then to heat treatment, greatly reducing labor intensity, reducing human interference factors, and improving the quality of steel ball production.

3. Due to the fast heating speed of the intermediate frequency and the short contact time between the surface of the round steel and the air, the surface oxidation of the round steel is greatly reduced, the amount of oxide skin generated is reduced, the utilization rate of the round steel is improved, production costs are saved, and the production efficiency of steel balls is improved.

4. The hot-rolled steel ball equipment adopts clean energy, which does not produce environmental pollution factors such as exhaust gas, wastewater, and noise during the production of steel balls. The cooling water is recycled and not discharged, which meets environmental protection requirements.

5. The wear-resistant steel balls produced by hot-rolled steel ball equipment have high overall hardness, high impact toughness, and low crushing rate, and are highly praised by users in various industries such as black and non-ferrous metal mines, thermal power plants, cement plants, refractory material plants, etc.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.