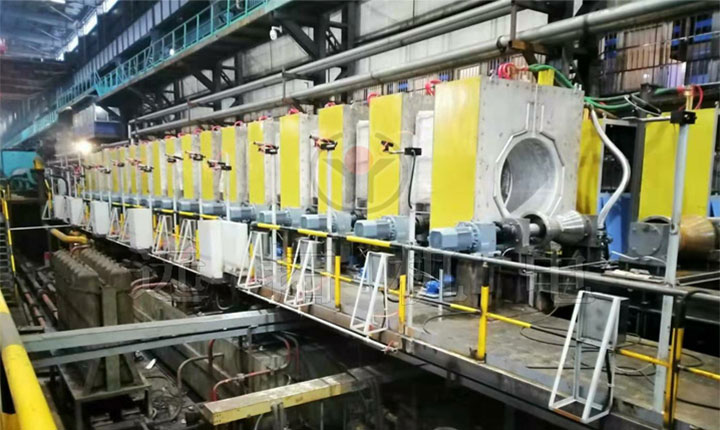

Thick wall steel pipe induction annealing line

Features:

Product Name: Steel pipe Annealing Equipment

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cr, 40Cr, 20CrMo, 35CrIo, 42CrIo, 40CrNIIO, GCr15, 65 Jm

50Cr, 3Cr2w8v, 20CrhmTi, 5CrhmMo, etc.

Workpiece diameter range: diameter 20mm~406mm

Workpiece length range: greater than 2m

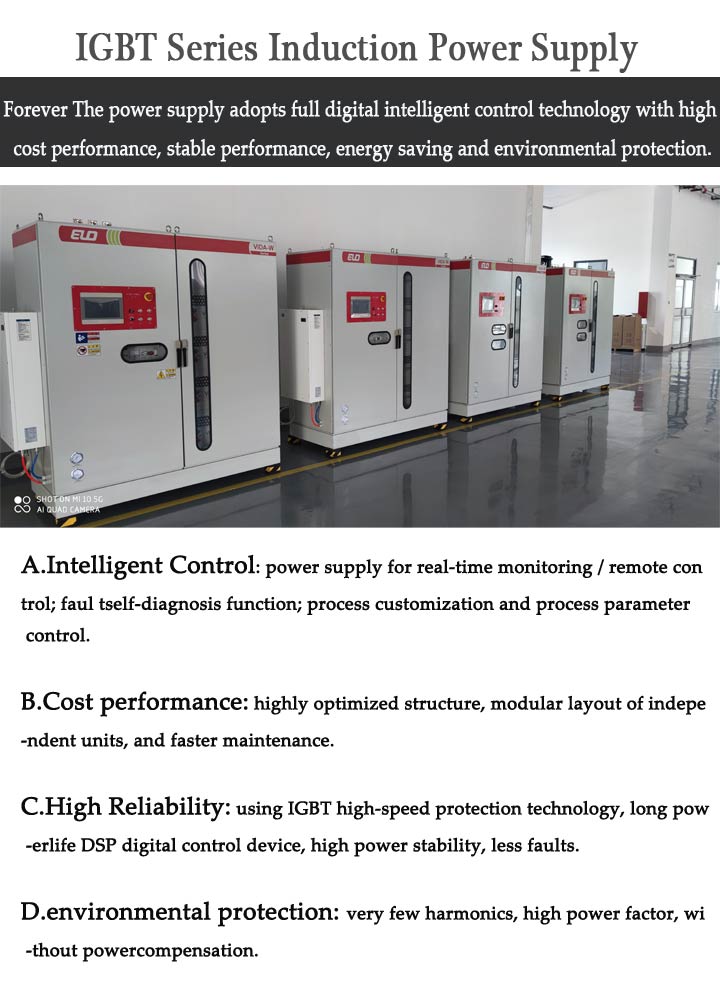

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

Product Detail

Application Video

Product Tags

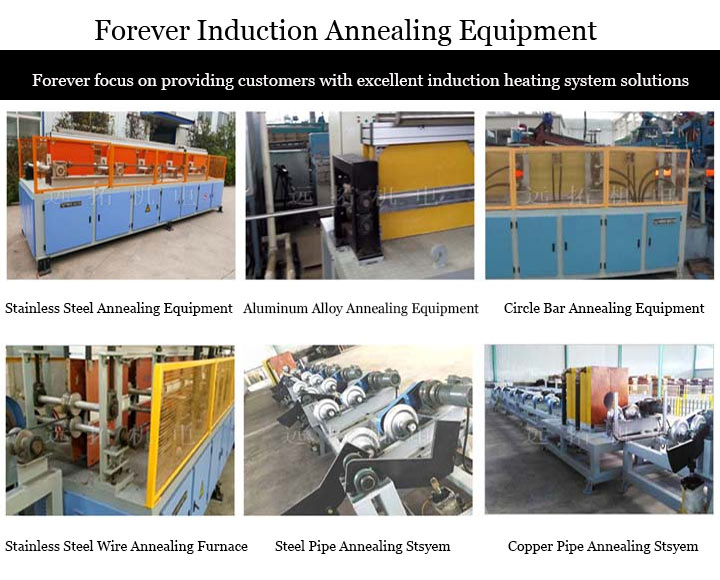

Yuantuo Electromechanical, with strong technical strength, strict quality management system, high-quality Thick wall steel pipe annealing production line services, has won the trust of users. It is a professional manufacturer of Thick wall steel pipe indcution annealing furnace in Hebei Yuantuo Electromechanical. Welcome new and old customers with demand to order the annealing heat treatment production line for thick walled steel pipes. Yuantuo Electromechanical Technology Engineer is dedicated to serving you and providing you with satisfactory and suitable medium frequency induction heating equipment.

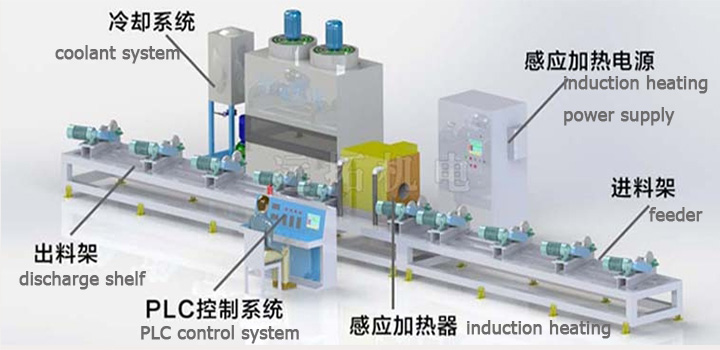

Thick wall steel tube induction annealing equipment control system: The annealing treatment control of thick walled steel pipes adopts high-performance embedded integrated chemical control computer centralized control, which has high control accuracy, stable operation, anti-interference, anti pollution, strong vibration resistance, and convenient operation. The control system of the annealing furnace for thick walled steel pipes is composed of Siemens PLC from Germany, Kunlun Tongshi Industrial Control Computer from Beijing, and the Leitai Temperature Measurement System from the United States. It can achieve comprehensive management of the system, automation of the annealing equipment for wall walled steel pipes, and self adjustment of the system.

The system adopts PLC centralized control, which can be manually or automatically controlled. The control system is reasonable, stable, reliable, and accurate, with strong signal anti-interference ability. At the same time, the system adopts an expansion module to collect temperature as a closed-loop feedback signal, which is processed by PLC program and adjusted accordingly to achieve closed-loop control function of the intermediate frequency induction heating equipment system.

After sales service for annealing equipment for thick walled steel pipes:

1. Adopting a “1+2″ service model, that is, from the time the thick walled steel pipe annealing equipment is sold, the project is tracked by one salesperson and one after-sales service personnel.

2. Free on-site guidance for installation and debugging. Responsible for training technical and operational maintenance personnel.

3. Provide a complete set of technical documents (including circuit diagrams) when delivering the annealing equipment for thick walled steel pipes.

4. After the self acceptance of the thick walled steel pipe annealing equipment, the intermediate frequency power supply cabinet is guaranteed for 12 months, with long-term maintenance and various spare parts provided year-round.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.