Steel Bar Heat Treatment System

Features:

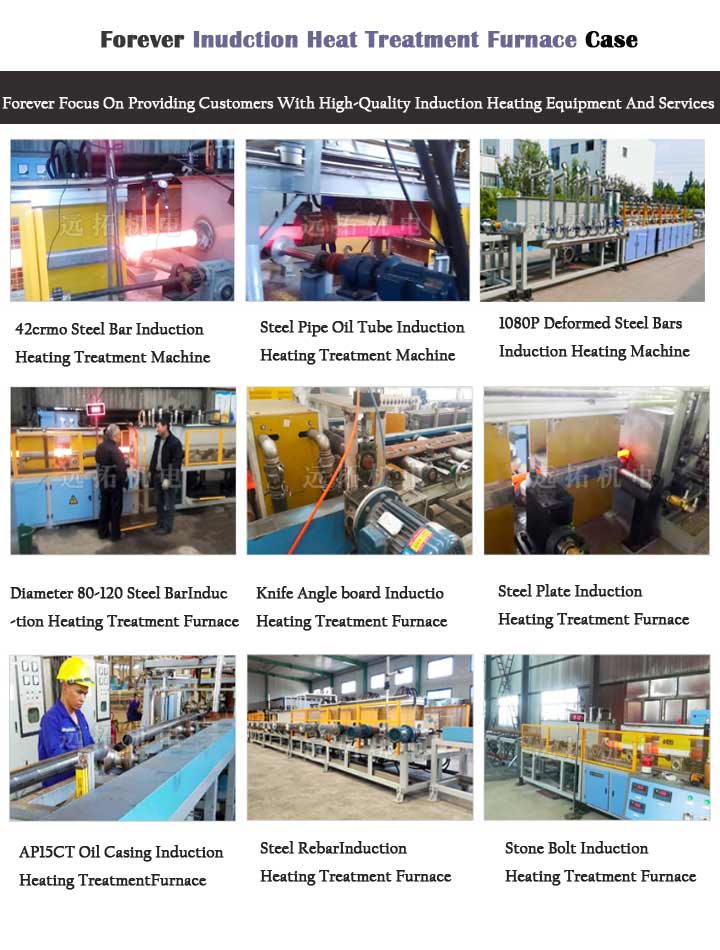

1.Application:Heat Treatment for Bars,Pipes,Strips,Wires,Upset Tubing,Pipeline,Oil Cylinder,Piston Rod

2.Available Power:100KW-10000KW

3.Non-standard Product;Professional Customization

Product Detail

Application Video

Product Tags

Forever Furnace can not only supply superior quality steel bar heat treatment system but also we are the Long bar heat treatment system specialist who can provide you the most suitable solutions!

Steel Bar Heat Treatment System Principle:

With easy operation and automatic infrared thermometer for the equipment,the user can monitor and control the temperature of the steel pipe during the whole processing and control the production cycle time with the time reply.When the equipment start to feed the material,the infrared thermometer will leave the pipes and rotate an angle,then the pusher will push the bars to induction heaters.Next the rollers will transmit the heated pipes to the roller end.Then feeder will turn the steel pipe to the discharging rack.During the transmitting process,the pusher will return normal and the next pipe will turn to the feeding rack.At the same time,the thermometer will be back to measurement position and contact the pipe head.Then one time feeding and discharging is over.Usually,the production line will be equipped with one holding furnace to make the pipes have uniform heating.

Forever Furnace heat treatment system can be used for steel bar and steel pipe heating before forging,hardening,tempering,hot rolling,shearing in steel plant,cement mill and mining engineering.

Reliable Performance of the Steel Bar Heat Treatment System:

(1)IGBT AC variable frequency driving system can satisfy adjustment requirement.Low cost,simple construction and reliable running.

(2))IGBT induction heating power increase the system reliability and stability.

(3)All the induction heating system and transmission system controlled by PLC,induction heating system controlled by output close-loop and transmission system controlled by speed close-loop make sure that the machinery transmission speed and output power of induction heating system remain constant.

(4)The technology of processing parameters catalog storage make sure that every specification can be produced in the same processing condition.

(5)Temperature compensation technology eliminate influence of the temperature fluctuation to the product quality.

As an experienced and professional producer and exporter,Forever Furnace focuses on quality and service improvement of induction heating equipment.We believer you will be satisfied with us once you give us an opportunity.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.