Medium Frequency Hardening and Tempering Furnace

Features:

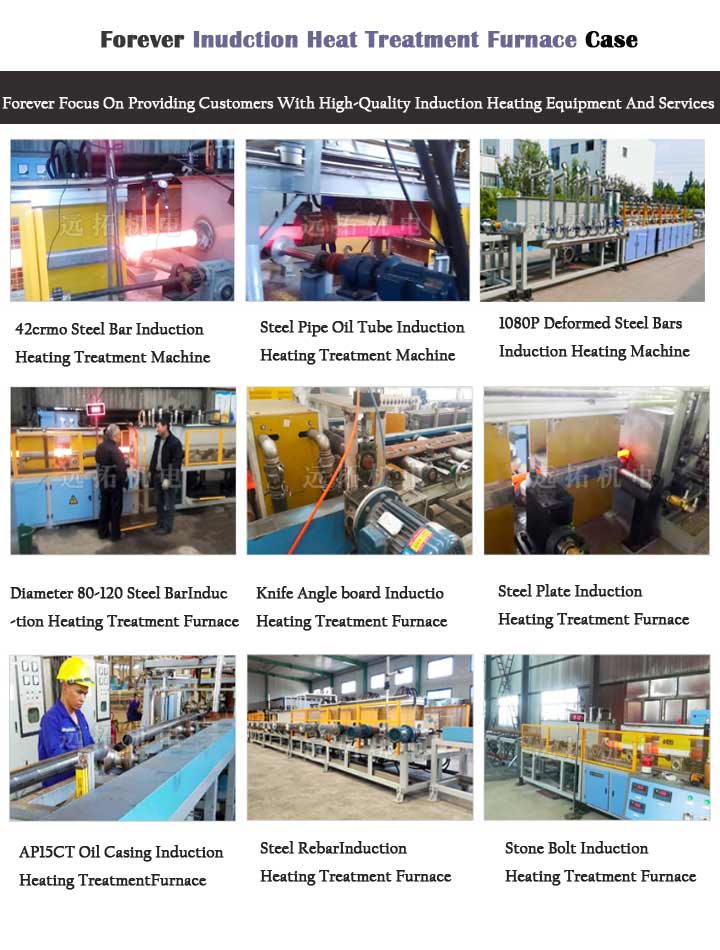

1.Application:Heat Treatment for Bars,Pipes,Billet,Slab,Shaft,Guide rail,Tracklink,Railway parts

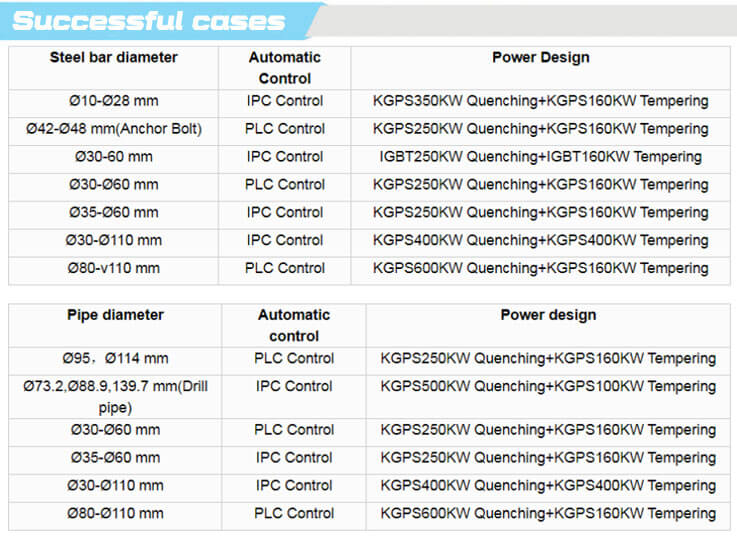

2.Available Power:100KW-10000KW

3.Non-standard Product:Professional Customization

Product Detail

Application Video

Product Tags

Specialized in producing medium frequency hardening and tempering furnace for more years,Forever Furnace can make hardening and tempering furnace as per customer’s process requirements such as heating temperature, heating efficiency.

With America Raytek infrared thermometer and PLC closed-loop control system, our medium frequency hardening and tempering furnace can monitor and control heating temperature easily.

The induction coil should be constructed with 99.95% pure electrolytic copper tubing, and should be wound to tight tolerance to provide high electrical efficiency.

Required no. of temperature switches to monitor the temperature of each segment cooling water of coil shall be provided over the entire length of the coil.

The Process of Medium Frequency Hardening and Tempering Furnace

1.Automatic Feeding System: The workers put the bars on the storage rack and well,then the automatic feeding system will transmit the steel bars to the parallel rollers.

2.Induction Hardening:With stable running speed of the driving system,the transmission system will deliver the bars in the induction heater.The infrared thermometer will monitor and control the bars temperature automatically in the processing of Reheating-Temperature-Measurement-Raising Temperature-Temperature Measurement. After pipe temperature reaches to the target quenching temperature,they will be cooled in the cooling device. Then the transmission system will deliver the bars to the feeding system to wait for the next heat treatment.At the same time, the hardening rejection will be isolated.

3.Tempering System:The bars after hardening processing will be transmitted to the induction heaters for reheating under the infrared thermometer control.Then the bars will move to the cabinet to preserve heat.After holding temperature time,the straightened bars will be sent to to the parallel rollers.

4.Automatic Discharging System:The bars will be transmitted to the discharging system for natural cooling.

5.Inspection and Storage.

High Automation for Medium Frequency Hardening and Tempering Furnace

1)Computer control for all process parameters and will store parameters in the PLC. As long as the operators call up the corresponding process parameters, the system can start.

2) Friendly man-machine interfaces: The operator can operate without basic training, and the product quality is independent of the operator.

Having advanced induction heat treatment process, strict quality control system,superior after-sales service,Forever Furnace gained good reputations from our users. We will continue working hard to meet users’ requirements.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.