Pipe hardening and tempering furnace

Features:

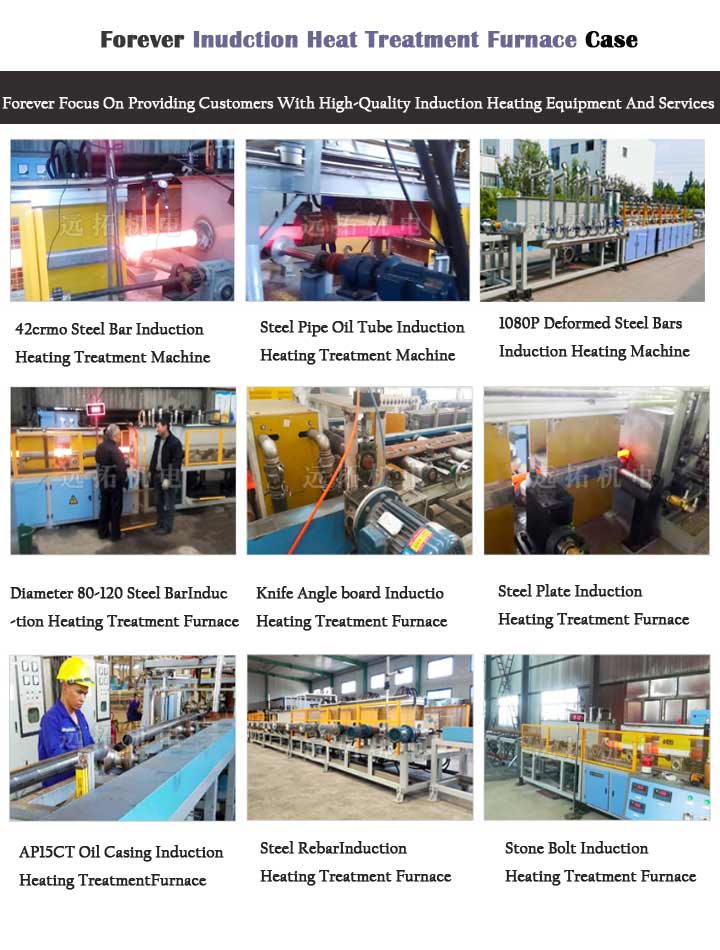

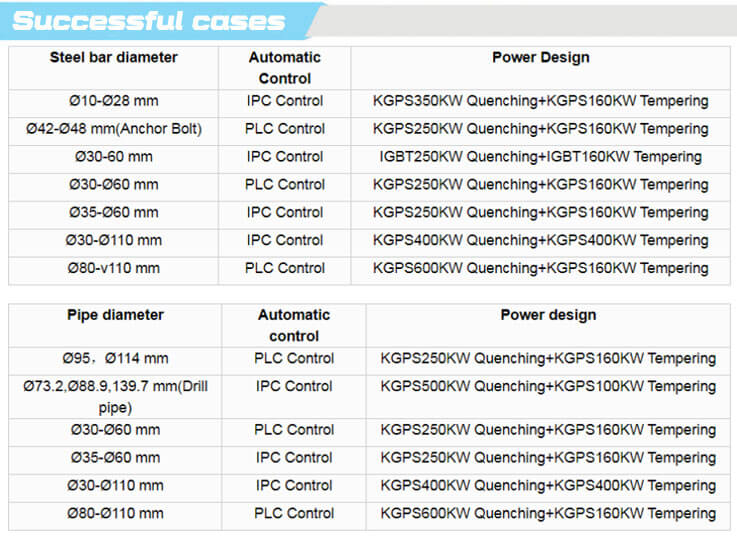

● Application: Heat treatment line for pipe, long bar, plate, billet

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

Forever can provide users with various kinds of pipe hardening and tempering furnace, which is running well in user’s plant. Our pipe heat treatment furnace products include: Tubing quenching and tempering line, drill pipe quenching and tempering line, seamless pipe induction quenching machine, pipeline induction annealing system.

● Equipment name: pipe hardening and tempering furnace

● Equipment name: pipe hardening and tempering furnace

● Equipment brand: Forever

● Non-standard customization: yes

● Workpiece material: carbon steel, alloy steel, etc.

● Delivery time: 30 days

● Quality warranty period: 1 year

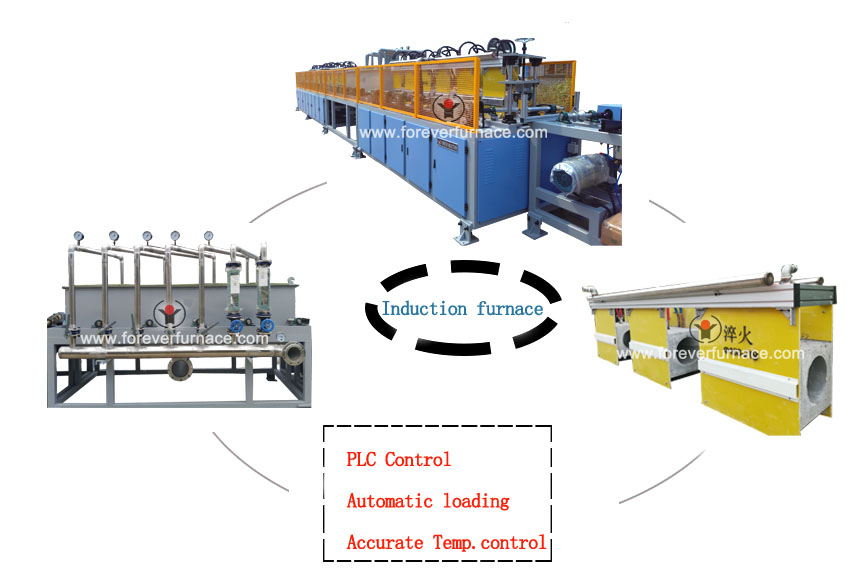

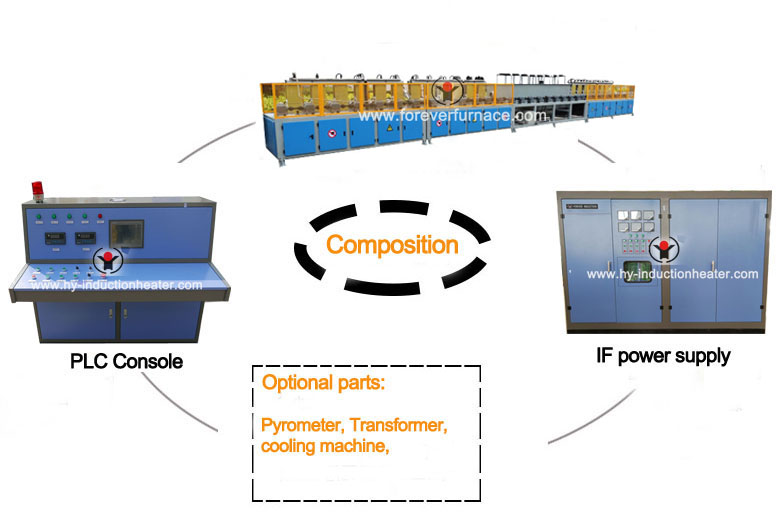

Several configurations of pipe hardening and tempering furnace:

1. Intelligent quenching intermediate frequency power supply (system for controlling pipe quenching)

2. Intelligent tempering intermediate frequency power supply (system for controlling tempering of pipes)

3. Quenching inductor group and tempering inductor group (the number of quenching and tempering furnace bodies designed according to the customer’s workpiece size)

4.Resonant capacitors and furnace cabinets (including stainless steel pipes)

5.Quenching water tank (including stainless steel water spray ring multiple groups, flow meter and conveyor roller)

6.Pipe induction hardening and tempering equipment connection cable (Connect from intermediate frequency power supply to the capacitor cabinet to make the equipment run, just like the charger we need to charge the phone)

7. Input and output roller table (the workpiece rotates and feeds at a constant speed, which can make the pipe heated more evenly)

8. Quenching and tempering infrared temperature measuring device (with American Raytek infrared thermometer to display the temperature of the workpiece in real time, so that the workpiece can be viewed at any time during the quenching and tempering process)

9.The central console (including frequency control and temperature control, Huayan IPC, remote start, etc.) its role is to operate the entire quenching and tempering equipment directly on the center console, only one person can operate the entire set of equipment, saving Labor, saving costs.

10. Independent gear reducer drive roller (water-cooled roller)

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !