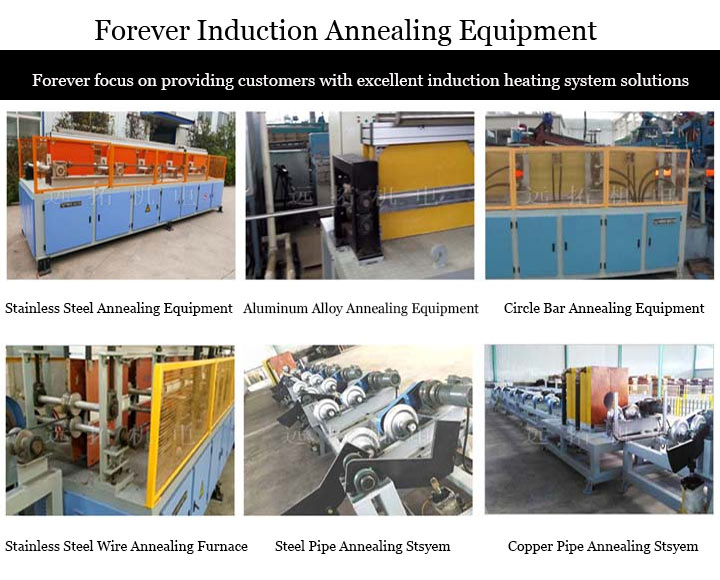

Hebei Forevero Electromechanical Equipment Manufacturing Co., Ltd. is a professional manufacturer of Steel pipe annealing equipment and continuous annealing furnaces for steel pipes. Forever Electromechanical has multiple technical engineers who have worked in the electrical and mechanical fields for many years. All colleagues of Forever Electromechanical adhere to the principles of integrity, quality, brand, technology, and service, providing you with comprehensive high-quality services. Welcome to inquire about the stainless steel tube annealing furnace. We, Forever Electromechanical, are dedicated to serving you.

Steel pipe annealing furnace fire process:

When using a new type of IGBT Steel pipe induction annealing furnace , the induction heating ring is made into different specifications of circular induction rings according to the size of the steel pipe. Through a guide pulley, the annealing part of the steel pipe is pushed into the induction ring. After starting the induction heating equipment to complete the annealing program, the steel pipe is removed and the workpiece is replaced for annealing.

Characteristics of Steel pipe induction annealing machine :

1. The entire steel pipe annealing furnace adopts FLC infrared temperature measurement control, which can automatically adjust the power supply or production efficiency according to the user’s set steel pipe temperature. This is conducive to automatically adjusting the power supply or production efficiency in the event of incoming voltage fluctuations to ensure product qualification rate. The temperature curve and power supply current and voltage data record table are generated in real-time for future comparison and query;

2. The display and real-time generation of data record tables for steel pipe annealing furnaces are beneficial for users to refer to, compare, and query in the future;

3. The conveying roller is installed at an angle to achieve automatic rotation and heating of the heated tube body, resulting in more uniform heating; 4. The use of 304 stainless steel material for the rollers between the steel pipe heat treatment furnace bodies greatly improves the efficiency of the electric furnace and reduces energy waste.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-04-2024