Induction steel pipe annealing furnace is a heat treatment method that heats steel pipes to a temperature where phase transformation or partial phase transformation occurs, and then slowly cools them after insulation. The purpose of annealing is to eliminate structural defects, improve the structure, homogenize composition, refine grains, improve the mechanical properties of steel, and reduce residual stress; At the same time, it can reduce hardness, improve plasticity and toughness, and improve cutting performance. So annealing is not only to eliminate and improve the organizational defects and internal stresses left over from the previous process, but also to prepare for subsequent processes. Therefore, annealing belongs to semi-finished product heat treatment, also known as pre heat treatment.

This equipment is strictly manufactured according to the production process and technology, and the quality of the produced products meets the user’s process requirements

a. This equipment is suitable for bright heat treatment in the non-ferrous metal industry, copper industry, and other industries.

b. The key components of this equipment are imported, and the rest are made of high-quality domestic materials.

c. This equipment strictly adheres to quality control, and its performance is at the same level as foreign products.

d. The transmission adopts roller synchronous transmission, with variable frequency speed regulation, stability, and reliability.

e. The furnace is equipped with a powerful stirring fan, and the electric heating elements are arranged reasonably. The temperature and atmosphere inside the furnace are evenly distributed, resulting in high-quality products.

f. The strong cooling zone adopts a high-speed jet cooling system (patented by Qiaojia Furnace Industry) to enhance the cooling effect of the workpiece and ensure that the pipe cools within the specified time.

g. The support bearing is a special high-temperature bearing, which ensures smooth transportation and service life,

h. There is a debris removal port designed below the furnace to maintain cleanliness and improve quality.

i. The Steel pipe annealing equipment has complete and reliable electrical automatic control, safety interlocking, and alarm functions

j. The electrical control system adopts a programmable logic controller (PLC), which can cooperate with computers to monitor the production line

k. High degree of automation, no environmental pollution, smooth surface of treated parts, uniform hardness, and no oxidation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

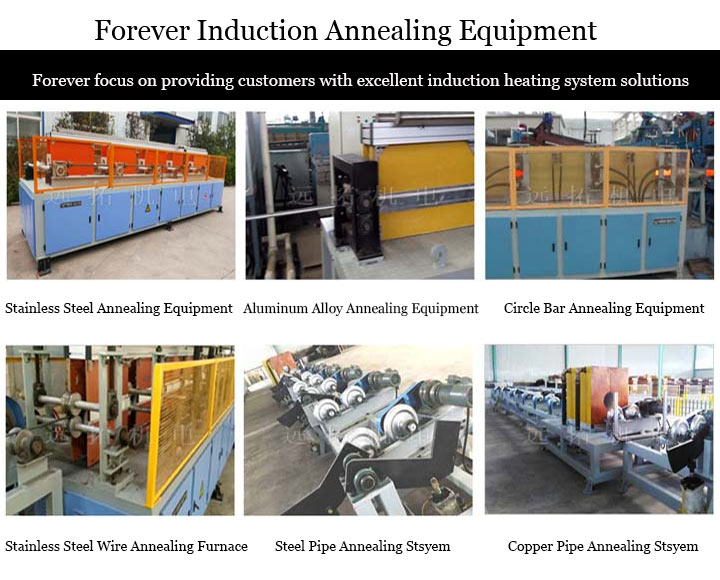

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 11-01-2023