Purchase high-quality steel bar quenching and tempering furnace FOREVER Electromechanical Equipment Manufacturing Co., Ltd., focus on the research, development and production of induction heating equipment. The steel bar quenching and tempering furnace is controlled by IGBT induction heating power supply, with low power consumption, stable performance, uniform heating, no bending and deformation of the steel bar after quenching and tempering treatment, and there are many steel bar quenching and tempering furnace schemes and video cases. Customers who need it can directly consult our telephone.

Technical process parameters of steel bar quenching and tempering furnace:

Equipment brand: FOREVER Electromechanical

Non-standard customization: Yes

Workpiece material: carbon steel or alloy steel]

Diameter of steel bar: above 20

Steel bar length: more than 2m

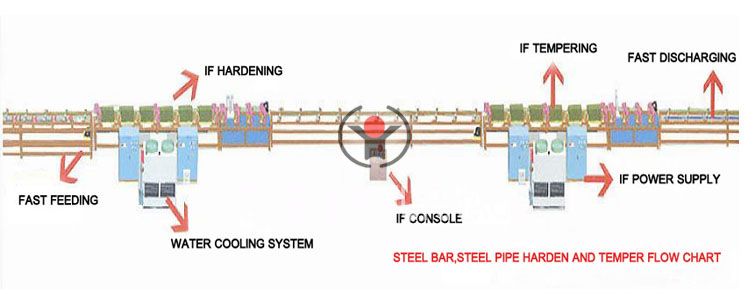

Configuration and composition of steel bar quenching and tempering production line :

1. Quenching medium frequency power supply range: IGBT160-1300KW

2. Tempering medium frequency power supply range: IGBT160-750KW

3. Quenching and tempering inductor (including capacitor bank, water circuit, gas circuit, etc.)

4. Closed cooling system for medium frequency power supply and inductor

5. Copper bar connecting wire of steel bar quenching and tempering furnace (connection between power cabinet and induction furnace)

6. Input and output system of steel bar quenching and tempering heat treatment production line (the workpiece rotates at the same time, feeds at the same speed, and operates stably, the speed is adjustable, and the heating is more uniform)

7. Quenching and tempering spray system

8. Quenching and tempering infrared temperature measuring device (equipped with American Raytheon infrared thermometer to display the temperature of the workpiece in real time, so that the temperature uniformity of the workpiece can be observed at any time during quenching and tempering)

9. PLC control system (can control the operation of the whole mechanical part, human-machine interface, all-digital, highly humanized operation)

10. The central console (including variable frequency speed regulation and temperature control, Huayan industrial computer, remote start, etc.) is used to operate the whole set of PC steel bar tempering production line directly on the central console. Only one person can operate the whole set of medium frequency tempering equipment, saving labor and cost.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-16-2023