The oil drill pipe hardening and tempering production line is a key device used for tempering and heat treatment (quenching+tempering) of drill pipes, aiming to improve the strength, toughness, and fatigue resistance of drill pipes to adapt to complex underground working conditions. The following are the composition, characteristics, and technical points of this type of equipment:

Main equipment composition

heating furnace

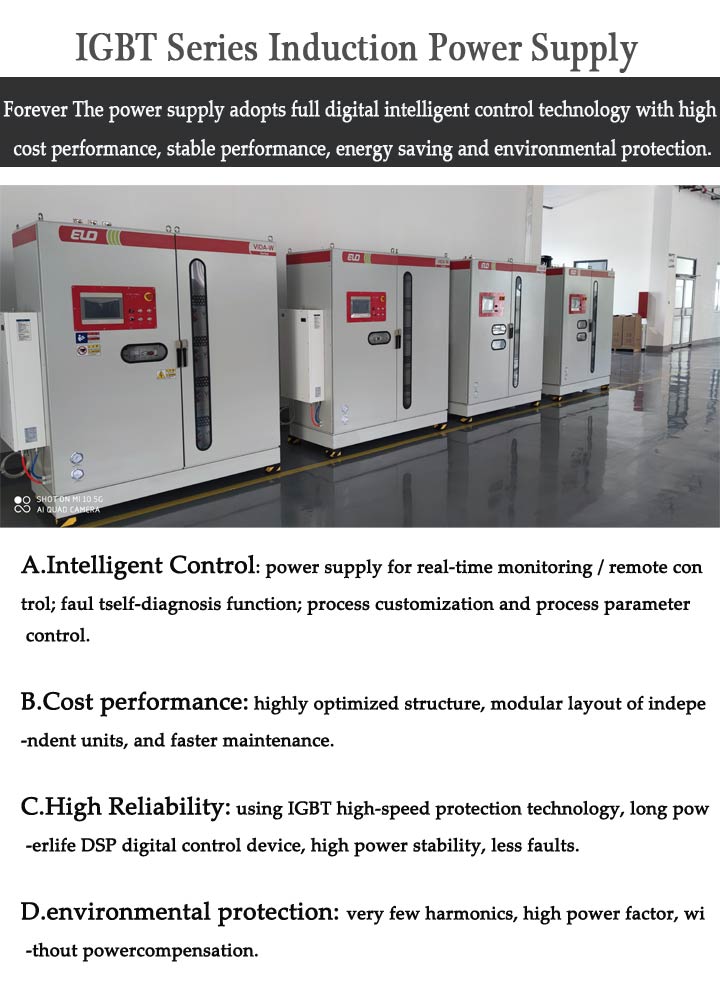

Type: Usually using medium frequency induction heating furnace or gas/oil furnace, modern production lines mainly use induction heating (high efficiency, precise temperature control).

Temperature range: Heat to 900~950 ℃ (depending on the material, such as AISI 4140 steel requiring austenitization at around 920 ℃).

Uniformity control: It is necessary to ensure that the entire length of the drill pipe is heated evenly to avoid local overheating or underheating.

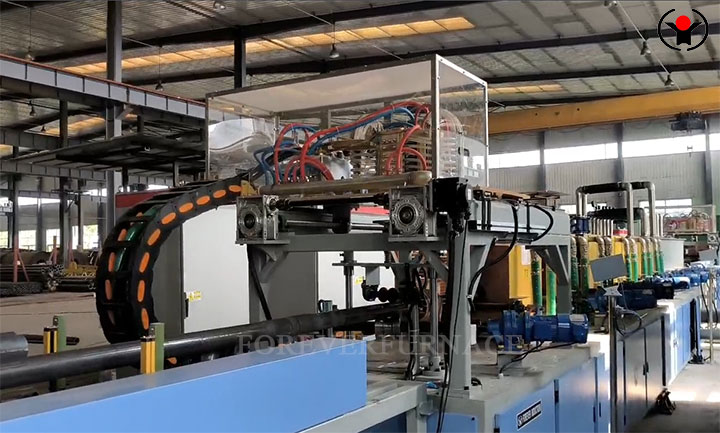

Quench system of the oil drill pipe induction heat treatment machine

Quenching medium: water-based polymer solution or oil (depending on the drill pipe material, high alloy steel may be quenched with oil).

Spray device: Multi nozzle annular spray design ensures synchronous cooling of the outer surface and inner hole of the drill rod.

Cooling rate control: It is necessary to meet the requirements of material martensitic transformation and avoid deformation or cracking.

Tempering furnace

Type: Gas stove or electric heating stove with forced hot air circulation.

Temperature range: 500~650 ℃ (adjusted according to hardness requirements to reduce brittleness and maintain strength).

Insulation time: usually 2-4 hours to ensure sufficient tissue transformation.

auxiliary equipment

Automatic transmission system: roller conveyor or robotic arm, realizing the transfer of drill rods between heating, quenching, and tempering processes.

Straightening machine: After quenching and tempering, the straightness of the drill rod is corrected (residual stress may cause bending).

Non destructive testing equipment: ultrasonic or eddy current testing to identify internal defects after quenching and tempering.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-03-2025