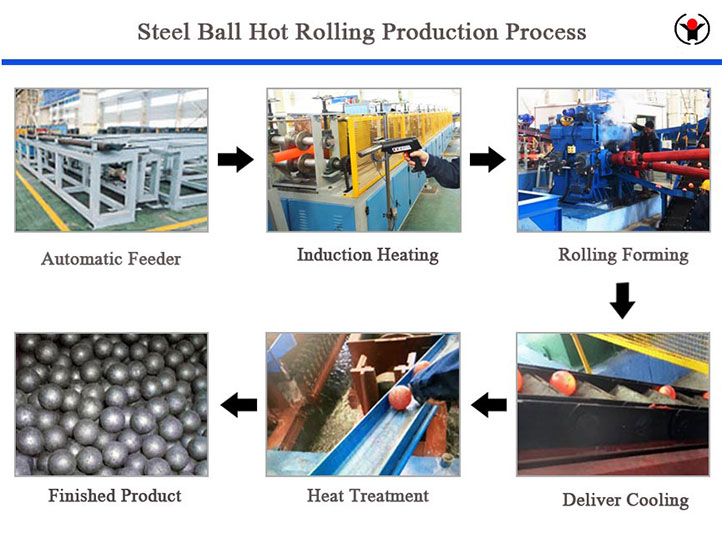

The Forever steel ball hot rolling production line mainly includes the following types:

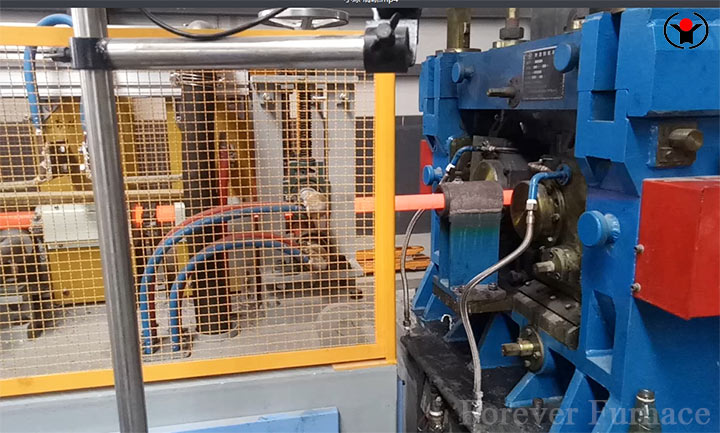

Steel ball rolling mill

Working principle: The steel ball rolling furnace uses two rolls with special spiral hole patterns to rotate in the same direction, causing the round bar blank to rotate in the opposite direction between the rolls and move forward, thereby rolling the round bar into steel balls.

Features: High production efficiency, large output, high degree of mechanization and automation in ball rolling production, minimal human intervention, stable quality of steel balls produced, good hardenability, dense metallographic structure, fine grain size, and no deformation.

steel ball hot rolling equipment

Function: Used to heat steel ball blanks to the appropriate temperature for rolling.

Features: Can achieve PLC closed-loop control, high degree of automation, precise temperature control according to different steel ball sizes and production requirements, ensuring the quality and performance of steel balls.

Intermediate frequency electromagnetic induction heating furnace

Working principle: By using a medium frequency current to generate an alternating magnetic field through an inductor, an induced current is generated inside the steel ball blank, thereby achieving rapid heating.

Features: Fast heating speed, high efficiency, low energy consumption, environmentally friendly and energy-saving. It can enable the steel ball billet to reach the required rolling temperature in a short time, and the heating of the rolling steel ball heating system is uniform, ensuring the quality of the steel ball.

Other Auxiliary Equipment

Round steel bar cutting equipment: used to cut round steel bars into steel ball blanks according to a fixed length.

Steel ball collection box: used to collect cooled steel balls.

Offline trolley type resistance furnace: used for tempering the rolled steel balls to obtain higher hardness and better toughness.

Cooling system: used to cool the rolled steel balls to ensure their quality and performance.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-21-2025