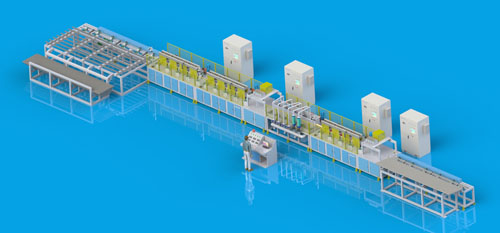

Steel pipe induction heating series has storage frame, quenching feeding machine, quenching heating module, quenching discharge machine, straightening machine, water spray cooling system, tempering feeding machine, tempering heating module and heat preservation module. Tempering discharge machinery, unloading rack and so on, using rational man-machine interface, PLC, industrial control computer automatic control, to reach the advanced level of the same industry in China, and has been praised and popularized by the special management department of coal mine equipment.

The steel pipe is pulled from the feeding table to the feed roller outside the quenching furnace. The feed joint of induction heating and quenching production line is photographed, the feed furnace door of quenching furnace is opened, the feed roller outside the quenching furnace and the feed cantilever roller table in the furnace are opened, and the steel pipe is sent to the quenching furnace by rotating rapidly at the same time. The positioning of steel pipe to quenching furnace is controlled by steel pipe positioning device and PLC. The steel pipe positioning device is generally composed of two photoelectric switches. It and PLC complete the length and speed measurement of the steel pipe and the positioning in the furnace. The controllable quenching hardness of this system: take HT-250 as an example to achieve HRC48-52 research and development: seamless steel pipe inner wall quenching equipment manufacturer un Guoyun Electronics, mature technology, stable performance, high efficiency and energy saving

Using intermediate frequency induction heating as heat treatment heating source has no pollution, safety, less oxide scale and low cost. The heating roller table ensures that the workpiece is heated evenly in the heating process, and the workpiece does not need to be straightened by the straightening machine after passing through the roller table, which reduces the cost. The spray quenching device makes the workpiece rapidly uniform and completely quenched in the continuous spray with the line, and the descaling device makes the surface of the finished workpiece bright to the true color. The drain table makes water and steam without tempering should be heated in the coil, and the service life of the induction heating coil is long.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-29-2019