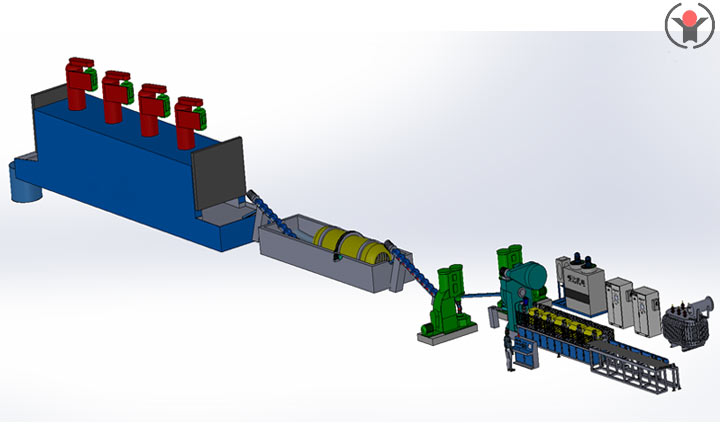

The Forever steel ball hot rolling production line is an efficient and automated steel ball production equipment designed and manufactured by Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd.

Main technical parameters of hot rolled steel ball production line :

● Workpiece materials: B2, B3, B6, 70Cr2, 75Mncr, 65Mn, 60Mn, GCr15, 40Cr, 45 #.

● Power supply system: KGPS200-6000KW or IGBT 200-2000KW, with an hourly output of 0.2-16 tons.

● Sensor design: variable pitch, temperature gradient design, higher efficiency.

● Elastic adjustable pressure roller: allows workpieces of different diameters to be fed at a constant speed, and the roller conveyor and pressure roller between the furnace bodies are made of 304 non-magnetic stainless steel and water-cooled.

● Infrared temperature measurement: Install an infrared temperature measurement device at the discharge end to ensure consistent temperature of the bar before entering the rolling mill.

● Energy Conversion: Heating to 930 ℃~1050 ℃, consuming 260~280 kWh of electricity

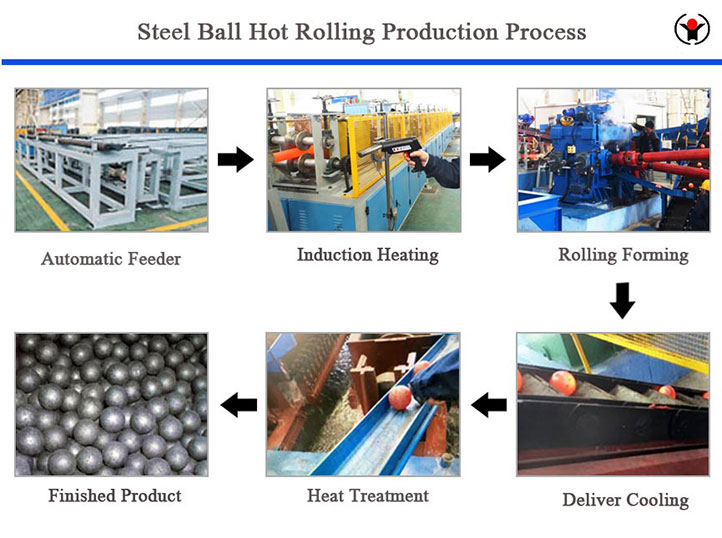

Working principle of Steel ball hot rolling heating furnace

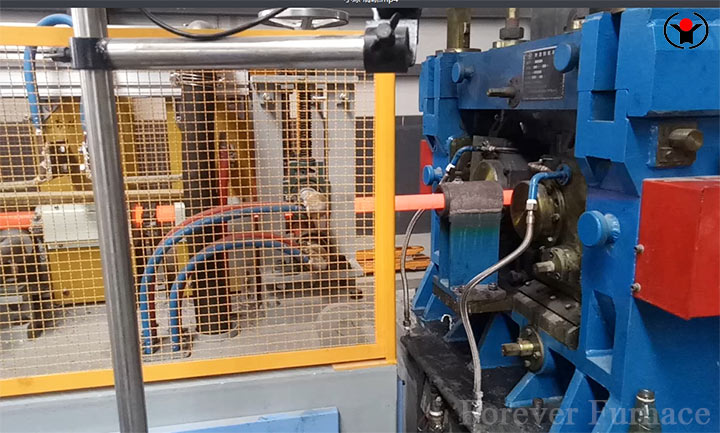

The working principle of spiral groove oblique rolling is shown in the figure. Two rolling rolls with spiral grooves intersect with each other, and the rolling rolls rotate in the same direction to drive the circular rolling piece to rotate and move forward. Under the action of the spiral groove, the rolling piece forms the blank of the rotating body part. The deformation of skew rolling is mainly due to diameter compression and axial extension.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-28-2025