The annealing process in Forever steel pipe induction annealing furnace is mainly used to repair the performance degradation of steel pipes caused by work hardening, stress concentration or deformation, restore their mechanical properties, improve processing performance or eliminate internal defects.

The core purpose of annealing process

Stress relief: Resolve residual stresses in steel pipes caused by cold processing (such as straightening, cutting) or welding, to prevent subsequent cracking or deformation.

Restoring plasticity: Softening the material through recrystallization to facilitate secondary processing (such as bending and expanding).

Improve organization: homogenize grain structure and enhance mechanical properties such as toughness and corrosion resistance.

Surface repair: Cooperate with subsequent shot blasting and coating processes to enhance surface quality.

Annealing process of the steel pipe annealing heat treatment machine

1. Preprocessing

Cleaning: Remove oil stains and rust on the surface of steel pipes (alkaline cleaning or ultrasonic cleaning).

Defect detection: Ultrasonic/eddy current testing marks areas that need to be repaired.

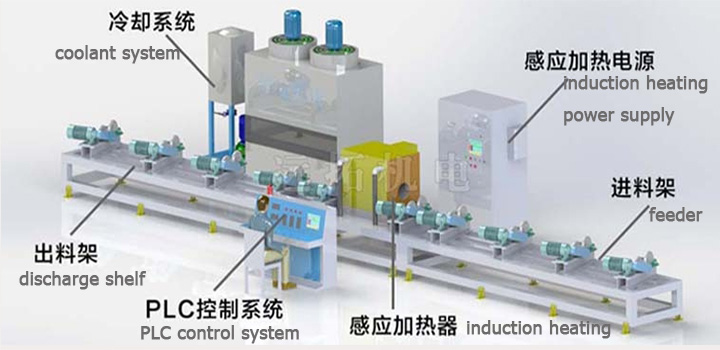

2. Furnace loading

Adopting roller bottom/trolley type annealing furnace to ensure uniform heating (avoiding stacking deformation).

3. Heating and insulation

Segmented heating: Slowly raise the temperature below 300 ℃ (to prevent deformation), and then raise it to the target temperature at a rate of 5-10 ℃/min.

Intelligent temperature control: PID algorithm with an accuracy of ± 5 ℃, avoiding over burning or under burning.

4. Cooling

After the Steel pipe annealing equipment is cooled to below 500 ℃, it is air-cooled. High alloy steel pipes need to be cooled under inert gas protection.

5. Post processing

Straightening: Fine tune the straightness under hot conditions (accuracy ≤ 0.5mm/m).

Testing: Hardness testing (HB ≤ 150), metallographic analysis (grain size ≥ 5).

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

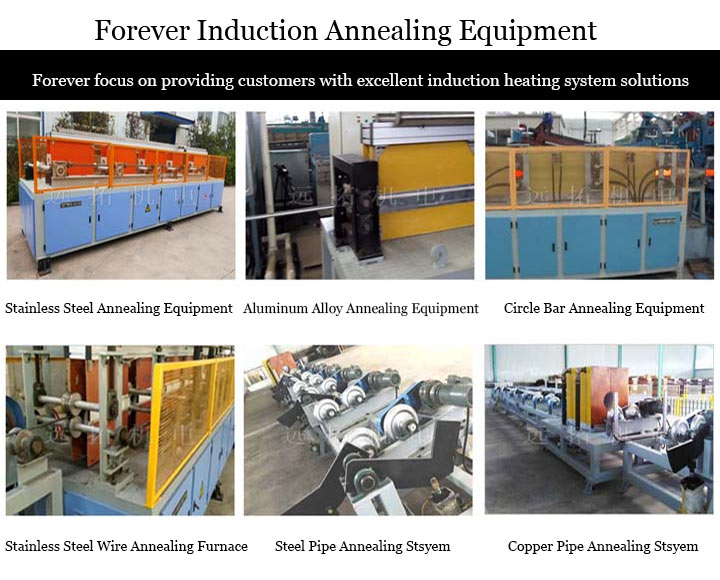

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-22-2025