Choosing the right equipment is crucial based on the material and size of the workpiece. Before starting heating, ensure that all workpieces are properly placed and configured.

Basic steps of steel pipe hardening and tempering furnace :

Preparation phase

Choosing the right equipment is crucial based on the material and size of the workpiece. Before starting heating, ensure that all workpieces are properly placed and configured.

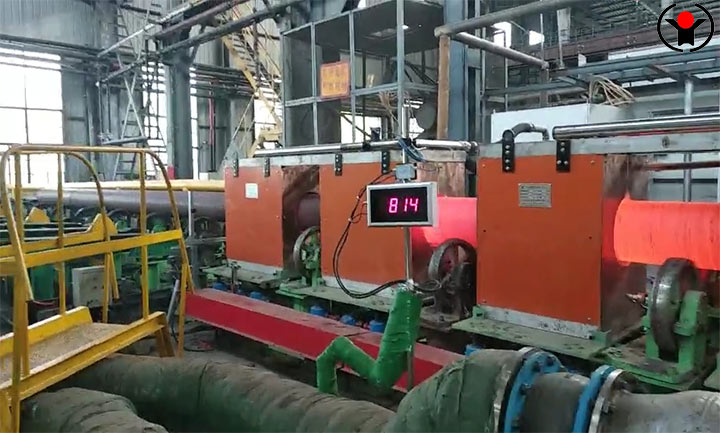

Heating stage

Set heating parameters for the steel pipe hardening and tempering heat treatment furnace equipment based on the type of material to be processed and the expected performance results. This includes ensuring that the frequency and power settings of the equipment can heat the workpiece to the appropriate temperature.

Insulation stage

After reaching the target temperature, maintain it for a certain period of time to allow for necessary changes in the internal structure of the material. The time and temperature control during this stage is crucial for the final product quality.

Cooling stage

Choose the appropriate cooling method based on material properties and desired final performance. Controlling the cooling rate of the steel pipe induction quenching and tempering furnace is a key step in ensuring that the material achieves the expected characteristics.

Adjustment and optimization of process parameters

Continuously monitor feedback data during the production process, adjust heating and cooling parameters to optimize production efficiency and product quality. Each material and component may require specific process settings.

Quality control and inspection

After completing the heating treatment, the steel pipes are subjected to hardness testing, microstructure analysis, etc. to ensure that each batch of products meets the technical specifications. This is a crucial step in ensuring product quality.

Troubleshooting and Maintenance

Regular maintenance is the foundation for ensuring the long-term stable operation of Steel pipe induction heat treatment furnace. Understanding common faults and their solutions can reduce downtime and improve production efficiency. Maintaining equipment cleanliness and regularly inspecting and replacing worn parts are necessary maintenance activities.

Controlling the process flow of steel pipe hardening and tempering heat treatment equipment is crucial for achieving high-quality products. Accurate parameter settings, effective monitoring, and timely adjustments can greatly improve the quality of material processing and production efficiency.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-07-2024