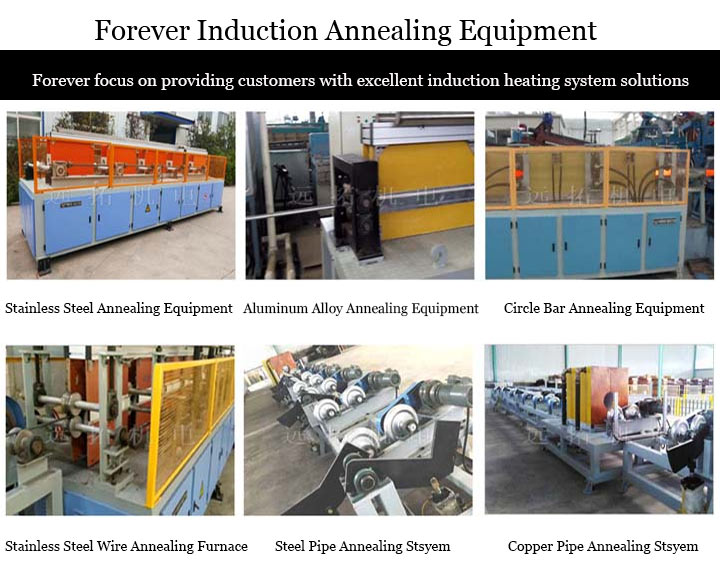

The steel pipe induction annealing furnace has significant technological advantages and industry competitiveness in the field of metal heat treatment, especially for steel pipes, rods, wires, etc.

1、 Core advantages

1. Efficient and energy-saving

Precise heating: Using the principle of electromagnetic induction, the steel pipe is directly heated locally, with a thermal efficiency of up to 60%~75% (traditional gas stoves only 30%~40%), and energy consumption is reduced by 30%~50%.

Rapid heating: The heating rate can reach 200~300 ℃/s, shortening the annealing cycle and improving production efficiency.

On demand heating: supports segmented heating (such as annealing only the weld seam) to avoid energy waste.

2. Accurate temperature control

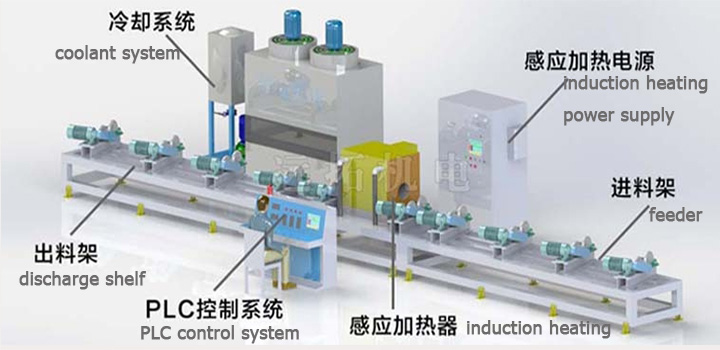

Closed loop temperature control system: Infrared thermometer+PLC dynamic adjustment, temperature deviation within ± 5 ℃, ensuring annealing uniformity (avoiding overburning or uneven hardness).

Multi stage process programming: temperature rise, insulation, and cooling curves can be set to meet the annealing process requirements of different materials (such as carbon steel, stainless steel, and alloy steel).

3. Automation and Intelligence

Integrated production line: It can be linked with straightening, cutting, testing and other processes to achieve fully automated production.

Remote monitoring: Supports Internet of Things (IoT) data collection, real-time monitoring of energy consumption, temperature, and device status, facilitating fault warning and process optimization.

4. Environmental Protection and Safety

Zero emissions: No combustion exhaust gas or dust pollution, in compliance with environmental regulations (such as China GB 28665-2012).

High safety: Closed design, avoiding the risk of open flames and gas leaks, and reducing workshop fire hazards.

2、 Advantages of Steel pipe annealing equipment application scenarios

1. Adapt to complex working conditions

Material diversity: It can handle steel pipes with diameters ranging from 10mm to 600mm, and has a wide range of wall thicknesses (from thin-walled pipes to thick walled pipes).

Special requirements: such as demagnetization annealing of stainless steel pipes, stress relief of high alloy steel, etc.

2. Product quality improvement

Uniform metallographic structure: rapid heating and cooling reduce grain coarsening, improve the toughness and ductility of steel pipes.

Good surface quality: the oxide scale is reduced by more than 50% (compared to gas stoves), and the subsequent pickling cost is reduced.

3. Low maintenance costs

Modular design: Easy replacement of vulnerable parts (such as induction coils) and short downtime.

Long lifespan: The design lifespan of key components (IGBT power supply, water cooling system) exceeds 100000 hours.

The steel pipe annealing heat treatment machine of Forever has the core advantages of high efficiency, energy saving, precise temperature control, and intelligent environmental protection. It is particularly suitable for industrial scenarios that require strict quality requirements and continuous mass production, which can significantly reduce comprehensive costs and enhance product competitiveness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-06-2025