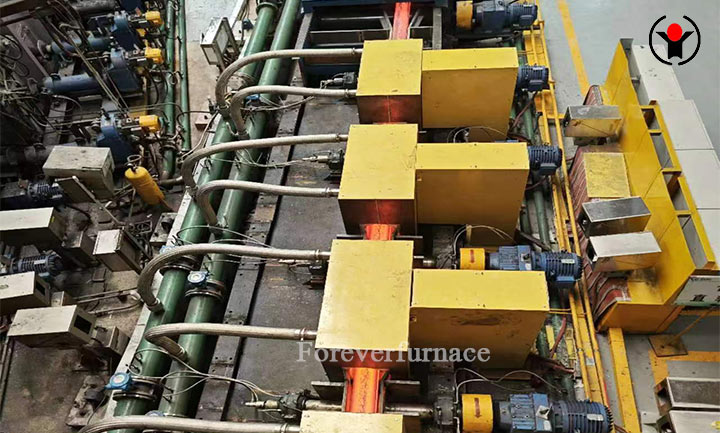

steel billet induction heating furnace is a device that uses the principle of electromagnetic induction to quickly and efficiently heat steel billets, and is widely used in industrial fields such as steel rolling, forging, and heat treatment. The following is a detailed introduction about the device:

1. Working principle

Electromagnetic induction heating: An alternating current is passed through an induction coil to generate an alternating magnetic field. The steel billet (conductive material) generates eddy currents in the magnetic field, which heats up due to resistance heating.

Skin effect: Current is concentrated on the surface layer of the steel billet, and heat is transferred inward through thermal conduction. The heating depth is related to the frequency.

2. Core components

Induction coil: a copper tube wound with water cooling to generate an alternating magnetic field.

Power system: Medium frequency (500Hz-10kHz) or power frequency (50/60Hz) power supply, with power designed according to production capacity requirements.

Conveyor system: roller or chain drive to ensure uniform speed of steel billets passing through the heating zone.

Cooling system: water-cooled protection coils and power equipment.

Control system: PLC or computer controls parameters such as temperature, speed, power, etc.

3. Main features

Efficient and energy-saving: Directly heating steel billets can achieve a thermal efficiency of 60-70%, much higher than flame furnaces (30-40%).

Fast heating: The heating rate can reach ℃/s, suitable for continuous production lines.

Accurate temperature control: Real time feedback from infrared thermometer, temperature deviation within ± 10 ℃.

Environmentally friendly and clean: no combustion exhaust gas, low noise, good working environment.

High degree of automation: can be integrated into intelligent manufacturing systems.

4. Application scenarios

Heating before rolling: Heat transfer before rolling of billets, slabs, etc.

Forging heating: Heating of the billet before free forging and forging.

Heat treatment: The heating process of annealing, normalizing, and other techniques.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-06-2025