FOREVER has a senior engineer who has worked in the field of induction heating for many years, and has rich experience and practice in the design, process, manufacturing, and management of stainless steel annealing furnace. It focuses on providing customers with excellent steel bar annealing furnace solutions and services. Our steel bar annealing furnaces are sold to multiple countries, where you can enjoy our high-quality services, stable and reliable product quality, and convenient transportation and geographical location! Welcome to visit the factory and negotiate business!

Process parameters of Bar heating equipment annealing furnace:

1. Workpiece material: Q195, Q235, 10 #, 20 #, 35 #, 45 #, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo, 40CrNiMo, GCr15, 65Mn, 50Mn, 50Cr, 3Cr2W8V, 20CrMnTi, 5CrMnMo, etc.

2. Workpiece diameter range: 10mm~150mm in diameter

Workpiece length range: over 2m

3. Intelligent intermediate frequency power supply power range: KGPS160KW-8000KW

4. Power consumption: calculated based on the material and diameter of the customer’s workpiece, the temperature at which the workpiece is heated, and the operating speed.

Features of steel bar annealing furnace:

1. The MCSV7.6F intermediate frequency intelligent series resonant power supply control system is mainly composed of three parts: a main control board, a rectifier trigger board, and an inverter trigger board. Its core components adopt high-performance, high-density, large-scale dedicated DSP+FPGA composite integrated circuits, enabling all circuits to be digitized. All parameters can be digitally corrected on a touch screen or remote device, featuring high reliability, strong anti-interference ability, and fast response speed.

2. Inductor design: Different inductor groups are designed based on different workpiece parameters. Wideband design ensures high heating efficiency for a wide range of workpiece sizes, ensuring that the performance of the workpiece meets the requirements.

3. The roller tables in front of the steel bar annealing furnace and between the furnace bodies are made of 304 non magnetic stainless steel, which are inclined and cooled by water, greatly extending the service life of the roller tables.

4. Forever’s newly designed roller table idlers use ceramic idlers, making the workpiece wear free and flame resistant during operation.

5. The annealed steel bar does not need to be straightened, without bending or deformation.

6. The online induction annealing equipment for steel bars is controlled by PLC, with a specially customized human-machine interface, highly user-friendly operation instructions, fully digital and deep adjustable parameters. It is easy to operate and can be learned in a few minutes. It has a strict hierarchical management system, and has the function of one-click restore.

7. After annealing, steel bars can achieve high strength, have good plasticity and toughness, which is commonly referred to as wear-resistant, durable, and long service life.

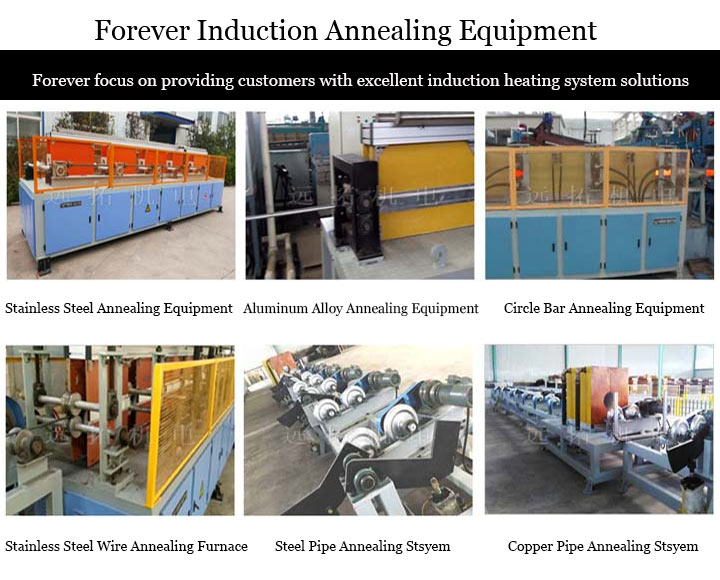

Our company also has other machines: steel tube heat treatment furnace 、steel bar induction heating furnace 、steel pipe induction heating furnace 、steel billet induction heating furnace 、continuous casting billet reheating furnace 、steel bar forging heating furnace 、ball hot rolling heating furnace and so on.

Welcome to call to inquire about the steel plate hardening furnace.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-31-2023