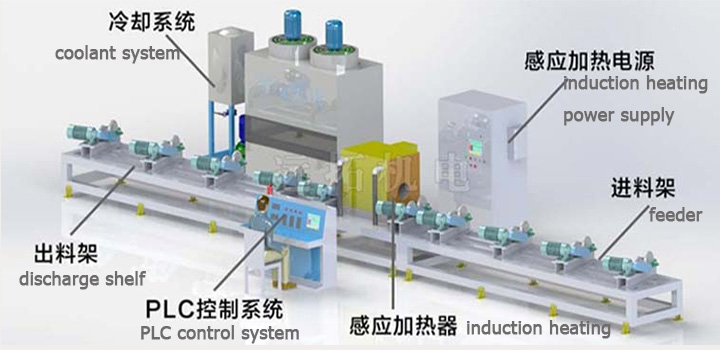

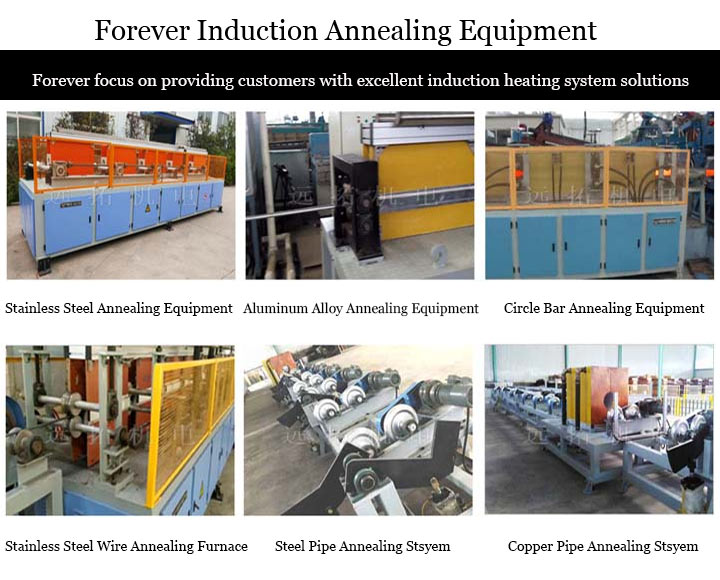

The new environmentally friendly product stainless steel annealing furnace is designed and produced by Forever Electromechanical. The stainless steel pipe annealing furnace is fully automatic and intelligent controlled by PLC, and the production process of the induction heating equipment is fully monitored by the computer, which is efficient and energy-saving. Forever Electromechanical has a team of experienced experts in the induction heating industry, with professional design capabilities, who can customize annealing heat treatment equipment for you.

The working process and characteristics of stainless steel pipe annealing furnace:

The heating sensor designed for the steel pipe annealing heat treatment machine adopts a quick change structure, which is convenient for maintenance and replacement.

The conveying roller adopts hollow water-cooled rotating roller, which will not cause bearing overheating and damage during induction heating. The stainless steel heat treatment production line designed by Yuantuo automatically adds oil to the bearing, which can extend the service life of the bearing and ensure its long-term stable operation.

The feeding method adopts inclined roller self rotating feeding, which infinitely ensures the uniformity of heating.

The entire working process of induction heating equipment has achieved fully automatic control of feeding, heating, and receiving processes.

To ensure that the workpiece does not deform during the annealing process, each equipment is equipped with a V-shaped roller that forms a certain angle with the bed axis. The V-shaped roller should have sufficient strength, rigidity, and wear resistance.

The transmission device adopts a continuously variable speed inverter produced by Fukagawa Corporation in Japan. The speed can be pre-set through numbers, making it easy to adjust the speed of entering the sensor.

The accuracy of the forward speed and rotational speed of the workpiece meets the requirements of the heat treatment process, and the operation is stable and reliable, with accurate control of the workpiece’s operating speed.

The steel pipe induction annealing furnace adopts PLC control, human-machine interface, fully digital, high depth adjustable parameters, and a one click restoration system, making operation simple.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-06-2025