Main technical parameters of steel bar induction heat treatment machine :

·Main application: Suitable for medium frequency heat treatment of steel bars, low-carbon alloy steels, round steels, bar materials, etc;

Power supply system: 160-1000KW/0.5-2.5KHz, hourly output of 0.5-3 tons:

Scope of application: 815-0150:

Conveyor roller conveyor: The axis of the roller conveyor forms an angle of 18-21 ° with the axis of the workpiece. The workpiece rotates while moving forward at a constant speed, making heating more uniform. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled·

Roller grouping: The feeding group, sensor group, and discharge group are independently controlled, which is conducive to continuous heating without creating gaps between workpieces;

Spray system: It adopts multi-stage spray cooling, and the pressure and flow rate between each level of spray ring can be adjusted to meet the requirements of different hardenability.

Temperature closed-loop control: Quenching uses a Leitai infrared thermometer and forms a closed-loop control system with Siemens S7, with high temperature control accuracy

Industrial control computer system: Real time display of the current working parameter status, workpiece parameter memory, storage, printing, fault display, alarm and other functions

Energy conversion: using quenching method, with a power consumption of 260-280 kWh per ton

Advantages and characteristics of steel bar hardening and tempering furnace :

● Good straightness

Adopting the Forever round steel bar hardening and tempering machine , the straightening function is designed during the heat treatment process, and the steel rod can achieve considerable straightness after heat treatment;

● Uniform heating temperature, high temperature control accuracy, small temperature difference, and no pollution

The Forever series variable frequency power supply is easy to directly and accurately detect changes in load current, thereby achieving closed-loop control of output power. The product has high precision in heating temperature control and small temperature difference between the core and the surface. There will be no harmful gases, smoke, or other environmental pollutants during the production process.

● High degree of mechanization and automation

The high degree of intelligence in power supply, temperature adjustment, frequency conversion automatic tracking, variable load adaptive, power automatic adjustment and other intelligent advantages enable “one click” operation, truly realizing automated and intelligent induction heating.

● Temperature closed-loop, intelligent, PLC overall operation control system

Infrared thermometer measures the heating temperature of the billet at the outlet of the induction heating furnace, monitoring for overheating or incomplete heating. To control the temperature of the billet within the target range. Reduced the generation of non-conforming products and ensured consistency in product quality.

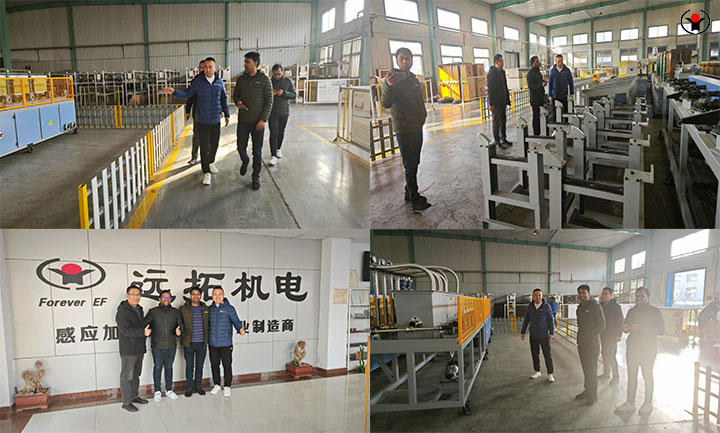

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-07-2025