Main technical parameters of steel billet induction heating furnace :

1. Power supply system: double rectifier 12 pulse or 24 pulse 1000KW ~ 12000KW/500HZ ~ 1200Hz single power supply is used independently or multiple power supplies are used in parallel.

2. Production efficiency: 40 tons to 300 tons per hour

3. Scope of application: 120mm-160mm square billet, 3000mm-1200mm long

4. Feeding system: each shaft is driven by an independent motor reducer, and multi shaft drive is set. A single frequency converter is used to control the multi shaft operation synchronously.

5. Guide system: 304 non-magnetic stainless steel guide wheel is adopted, and the axial direction of the guide wheel is kept with moderate elasticity to adapt to the bending of the billet within the allowable range.

6. Temperature closed-loop system: the closed-loop control system is composed of the American Leitai infrared thermometer and the German Siemens S7. The power supply is automatically adjusted according to the initial temperature of the billet entering the inductor and the feed speed, so that the heating temperature remains constant before the furnace is discharged.

7. Industrial computer system: real-time display of current working parameters and status, blank parameter memory, storage, printing, fault alarm, automatic power drop and constant temperature and many other powerful functions.

8. Remote console with touch screen or industrial personal computer system shall be provided according to user’s needs.

9. Specially customized human-computer interface and highly humanized operation instructions.

10. All digital, high depth adjustable parameters enable you to control the equipment easily.

11. Strict grade management system and perfect one click restore system.

12. Provide corresponding language switching according to different countries and regions

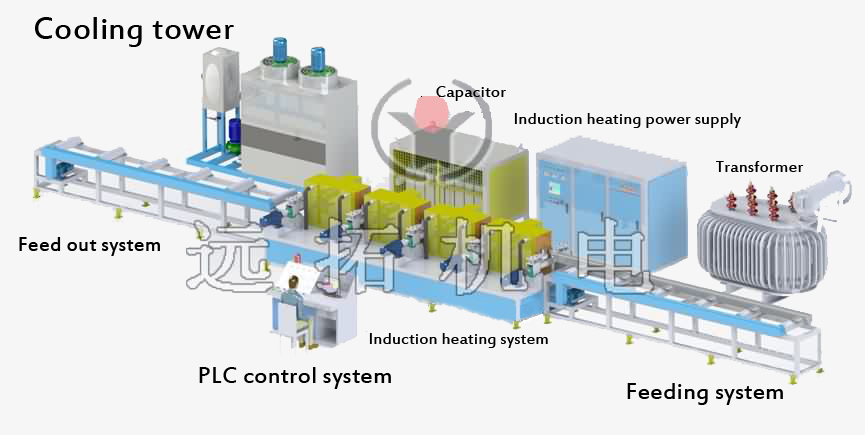

Composition of billet rolling heating furnace:

1. Intelligent series resonant medium frequency induction heating power supply

2. Furnace frame (including water circuit, circuit and water-cooled conveying roller table)

3. Capacitor cabinet bank

4. Induction heating furnace body

5. Connect wire/copper bar (power supply to furnace body)

6. Infrared temperature measurement system

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 12-20-2022